Ever since the onset of the Covid-19 pandemic, an unprecedented sequence of disruptions in global shipping and logistics has challenged the resilience and agility of fashion and apparel brands. Most responded with on-shoring and near-shoring strategies aimed at reducing the length of their supply chains.

Yet this has proved to be a delicate balancing act for brands. On the one hand, shifting production closer to the point of sale has proved costly and challenging due to skills shortages and the complex nature of global supply chains. On the other hand, spot container rates from Asia to the U.S. East Coast increased by 165% from December 2023 to February 2024.

MAS Holdings, a leading global apparel-tech conglomerate with a reputation for sophisticated, sustainable manufacturing, took a longer-term view of this emerging paradigm. Doubling down on an ambitious strategy of vertical integration, MAS acquired the assets of a running textile mill strategically located in the MAS Fabric Park – Thulhiriya. In addition to its location, the mill’s capacity for further expansion made it ideal for this purpose and by 2022, it was relaunched as TEXO (Pvt) Ltd.

Leveraging advanced computer-aided design (CAD) capabilities, Texo’s designer develops precise and artistic textile patterns.

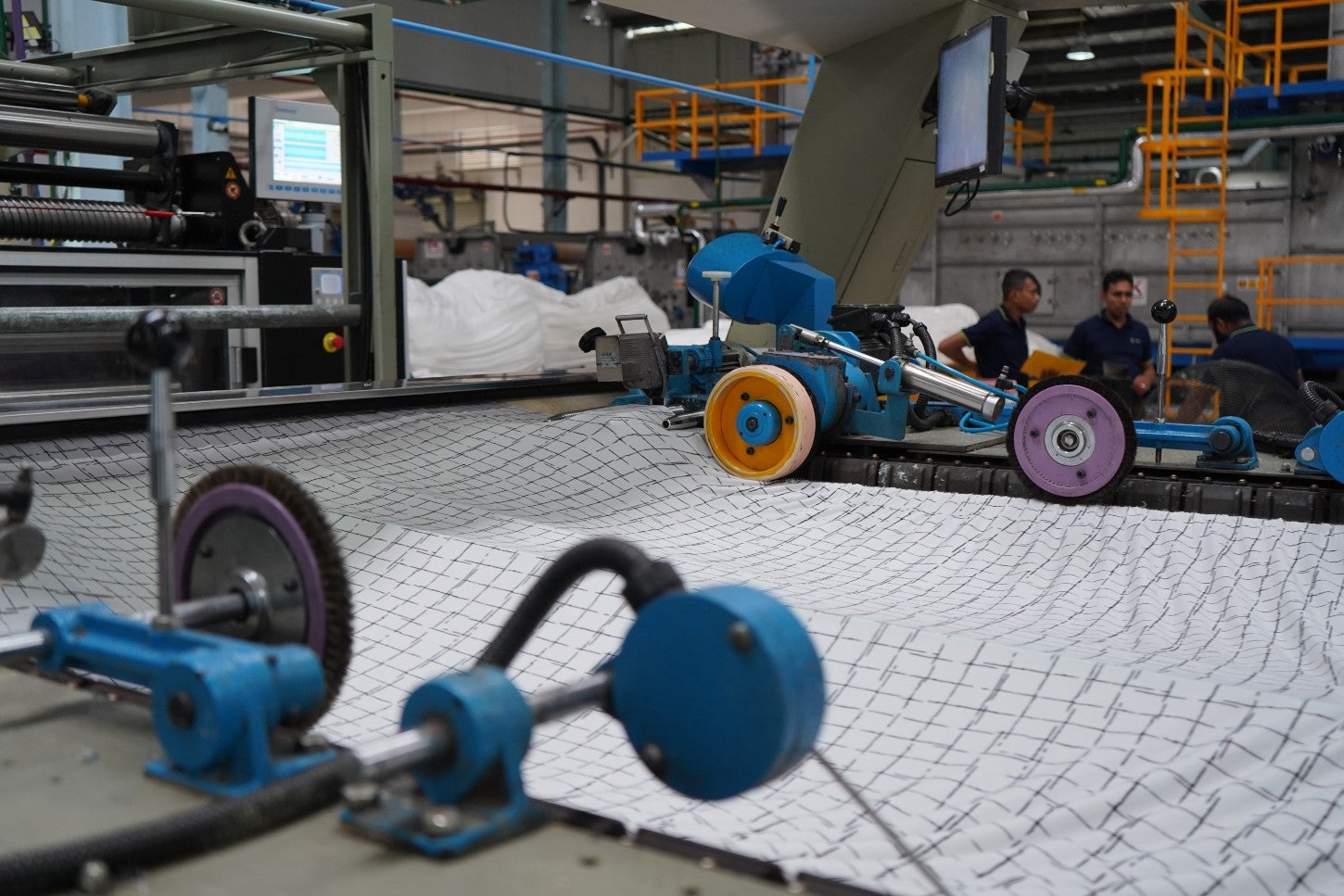

Texo has undergone significant transformation since its acquisition by MAS Holdings. It is on a path to standing as a globally competitive, cutting-edge fabric processing facility specialising in dyeing, printing and finishing of cotton-based fabrics. In turn, pioneering a supply chain strategy that is more cost-effective, agile, and environmentally friendly.

Given that Sri Lanka’s processed fabrics are predominantly imported, accounting for approximately 50-60% of the total demand, manufacturing out of Sri Lanka tended to depend heavily on the smooth flow of raw materials into the island on a ‘Just In Time’ basis. This created tight margins and left little room for error.

To address this, Texo has partnered with a leading large-scale supplier in India to procure raw fabric or greige in bulk. This raw greige is stored at Texo’s warehousing facilities. As orders come through, Texo provides value addition through dyeing, finishing, and printing processes—all within a single space and tailor-made to suit the needs of each customer order. Located within the MAS Fabric Park, Texo also harnesses the park’s cost and sustainability advantages, further reinforcing its value proposition.

“Vertical integration isn’t just a strategy; it’s a necessity for apparel manufacturers looking to stay ahead in today’s competitive landscape. Bringing fabric processing into the supply chain reduces reliance on imports, enhances control, and enables faster response to market trends. Texo’s commitment to vertical integration at a flexible scale embodies our innovative, forward-thinking approach to supply chain restrictions,” TEXO Chief Executive Officer Amandha Fernando said.

Beyond enhancing supply chain agility, Texo is also committed to sustainability across its operations. Fabric processing is a significant contributor to the fashion industry’s environmental impact, accounting for 53% of greenhouse gas emissions, according to a study done by Fabric For Good. Texo actively works to reduce its environmental footprint through energy-saving projects, the use of biomass for steam generation, biodiversity initiatives, waste recycling efforts and reduced water consumption. Texo has set its sights on achieving a target of reducing 25% of its emissions from its 2019 baseline by 2025.

A technician at work at Texo’s R&D lab

A stenter machine applying high-quality finishes to prints

“Fabric processing is critical to the textile value chain. It is where raw greige transforms into the customized coloured or printed fabric varieties that shape some of the world’s most sophisticated finished apparel products. This process requires the most specialisation as it needs to be executed with a very short lead time and needs to be close to the needlepoint. Our work is therefore foundational to the strength of Sri Lanka’s apparel manufacturing value proposition, helping to maintain its agility and cost-effectiveness without compromising on sustainability,” TEXO Director of Operations Dinouk Sirisena affirmed.

Texo’s journey is just beginning. Phase 1 of its expansion is set to be completed this year, with Phase 2 slated for completion by 2025. This expansion will more than double Texo’s existing capacity and enable the company to broaden its scope to include cotton poly fabrics and synthetics. Texo envisions its model as exportable to any manufacturer seeking to enhance its supply chain agility and verticality.

As Texo expands in scale, it remains committed to advancing sustainability initiatives and collaborating with major brands to drive supply chain resilience to new heights.

For more information about Texo, please contact Choliya Bandara, TEXO Deputy General Manager of sales and marketing, at choliyab@masholdings.com (+94779921255).