“The world is much more conscious of the environmental impact,” says Ana Hinojosa, Oritain Advisor and former CBP Executive Director. “In all industries, there’s a strong push for taking proactive measures for the sustainability of our planet and protection of our workers. But good intentions are not enough; the only way to police the integrity of your supply chain is by having full transparency and traceability of what actually goes into your products.”

The risks of unverified promises

“You can’t just take your supplier’s word for it,” Hinojosa warns.

Many brands source materials from developing regions where labour standards are not consistently enforced, leaving them in the dark about what’s truly happening on the ground. For years, they have leaned on suppliers’ written assurances and certifications, hoping everything checks out at the border.

“Suppliers want the contract,” she explains, “so they’ll tell you what you want to hear to get it.” While this may not come from a malicious place, it can lead to suppliers making promises they can’t keep, putting brands and importers at risk — financially, reputationally, and legally.

“Manufacturers have shades of grey in their accuracy around the content of different materials, ” she adds, “and what’s on the certificate might not match what is actually in the product.”

Protecting workers and their dignity

The global focus on forced labour has intensified. “Forced labour is gaining a lot more attention globally, and there are strong provisions already in the U.S.,” says Hinojosa, “but many are emerging across the world.”

The Fashion Transparency Index 2023 reveals that G20 countries import $468bn of goods at risk of modern slavery, yet only 12% of brands publish the names of any of their raw material suppliers—and just 6% of brands disclose the name of a specific facility or farm where the raw material is produced.

Brands cannot rely on signed papers from suppliers, particularly when the workers producing the goods may be subject to poor conditions, low wages, or even forced labour. The focus must shift to ensuring that workers are treated with dignity and respect, regardless of where they are located.

As Hinojosa explains, “Nobody says that conditions have to meet Western standards, but there are basic human rights that should be protected. Workers are human, and they should be treated with dignity and respect.”

Legislation squeezing in

“Forced labour regulations are already strong in the US and EU markets and getting stronger in other major markets,” Hinojosa explains. “Soon, companies will face greater scrutiny across the world, not just in a few select markets.”

A brand that only complies with regulations in one market will soon find itself facing similar requirements in others, making uniformity and consistency in the standards used to produce products absolutely essential.

“It’s not just about protecting your business from fines,” Hinojosa points out, “but also from reputational damage that can last for years.”

One of the growing challenges in complying with regulations is transshipment — where products’ true origins are obscured to avoid duties or bypass sanctions. If brands are not vigilant against such practices in order to stay in compliance with international trade regulations, it can lead to greater PR and financial consequences if caught.

“Brands must adopt a ‘trust but verify’ approach by establishing strict guidelines for suppliers regarding the manufacturing process and materials used,” Hinojosa advises. “It requires having a methodology and agreement in place to test and ensure the quality and content of what is going into those products is within the specifications of the brand.”

Brands need to build better relationships with suppliers, but that doesn’t mean letting blind faith stand in for trust-based, objective verification. Without verifiable, reliable data, brands can be exposed to risks they can’t see coming — until it’s too late.

Oritain verifies the source of truth in global supply chains

Oritain, a global leader in origin verification, uses forensic science to trace and verify the provenance of products and raw materials. The objective methodology can identify the location from which the raw material came, and it can do so whether the cotton is in raw form, yarn, fabric, or final garment, just by analyzing a sample. Cone Denim, Lacoste, and Supima are just a few of the leading brands using Oritain to deliver transparency and traceability in their supply chain.

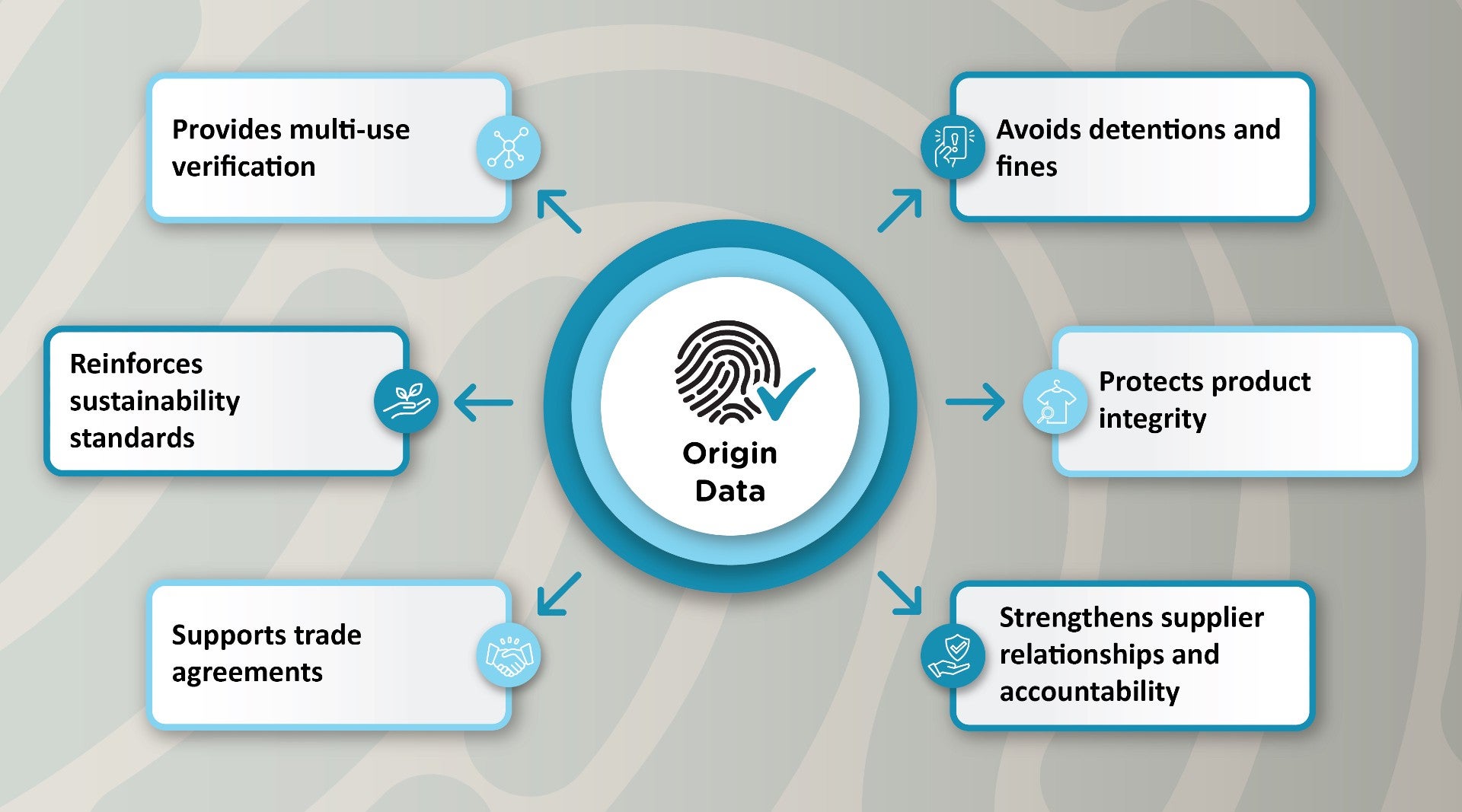

From mitigating shipment detentions and expensive fines that can derail an entire product line or fashion season to improving supplier relationships and boosting consumer trust, the return on investment (ROI) for verified origin data is high.

As Hinojosa says, “Investing in transparency pays off — not just in regulatory compliance, but in protecting your brand and building consumer loyalty.”

- Avoids detentions and fines: Accurate origin data from proactive testing provides brands with an insurance-like benefit. If 60-70% of a company’s revenue is based on cotton, verified data enables brands to mitigate risks, saving them hundreds of thousands of dollars in direct legal fees, missed merchandise windows, and storage costs.

- Protects product integrity: According to a Mintel 2024 report, 49% of women are buying fewer but better quality clothes. Brands need to have objective, verifiable data on their materials to ensure they’re getting exactly what they’ve contracted for — whether it’s Supima cotton or another premium material — avoiding costly substitutions and quality disputes.

- Strengthens supplier relationships and accountability: With the assurance of verified origin, brands can control the raw material that goes into products and cut out unnecessary middlemen. They can work directly with their suppliers to remedy any issues before they escalate.

- Supports trade agreements: Origin data helps meet specific qualification parameters of trade agreements, especially as supply chains shift and countries attempt to obscure raw material origins due to duties or sanctions. Since this is a matter of fraud rather than a simple import issue, clear evidence of material origins ensures compliance, preventing detentions, fines, penalties, and potential seizures.

- Reinforces sustainability standards: Mintel reveals that 62% of consumers agree that sustainability is important when shopping for clothing or fashion items. Origin data helps brands meet increasing sustainability reporting requirements for carbon measurement or modern slavery compliance and can be leveraged in marketing and PR efforts.

- Provides multi-use verification: If companies verify origin for one purpose, the same data can be reused for various compliance frameworks, from human rights due diligence to environmental protection and even FDA safety standards, reducing redundancies and increasing the value of every dollar spent on traceability efforts.

“Data doesn’t just help you avoid risks — it gives you a competitive edge,” says Hinojosa. When brands can objectively verify whether materials like cotton or polyester are sourced from regions known for forced labour or environmental exploitation, they gain consumer trust and differentiate themselves from competitors who may lack the same transparency.