Smartex Fact claims to address the challenges manufacturers face such as inefficiencies, quality concerns, and the need for manual inspections, all of which can drive up costs and hinder competitiveness.

The all-in-one digital factory management is said to offer automated insights into machine data, roll production statistics, and quality control. The digital solution also claims to eliminate inefficiencies, enhance quality control, and provide instant production notifications.

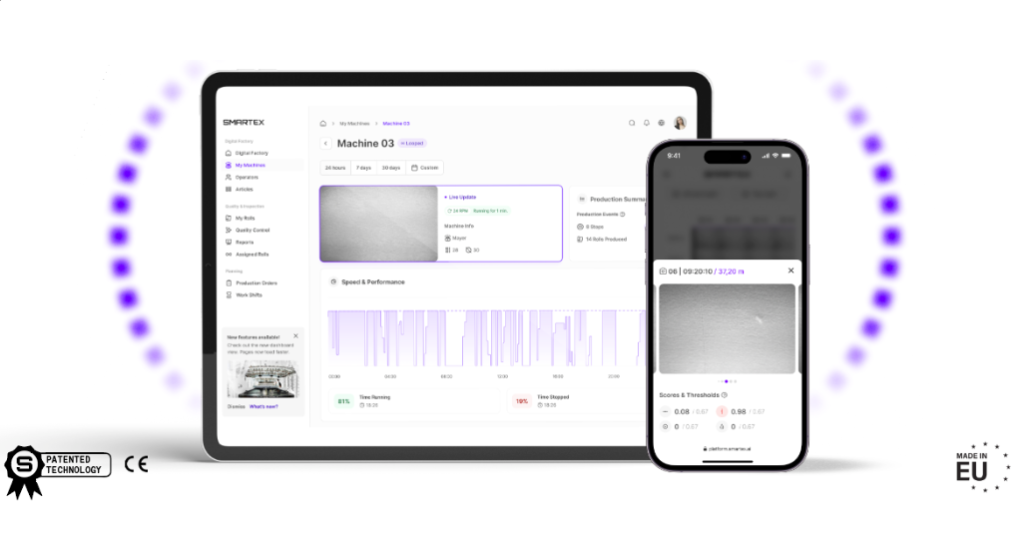

Smartex.ai co-founder and CEO Gilberto Loureiro said: “With Smartex Fact, users will be able to know when rolls don’t meet the requested quality or when production issues arise. And with the platform being easily accessible via desktop or any smartphone, it is basically your textile factory in your pocket."

Smartex Fact's key features

- Automatic roll grading: Smartex Fact allows users to establish their own quality standards for the automatic grading of knitted rolls based on defect severity and use a “fast-track option for Grade A rolls. The company said its Smartex Core AI-driven quality control guarantees consistent quality standards throughout the production process.

- Digital factory page: Users gain a comprehensive overview of their factory's current status, including the number of machines in operation and rolls produced on any given day.

- My machines page: Offers precise data on the performance of every machine powered by Smartex within the factory, including revolutions per minute (RPM) speed and operating time.

- My rolls page: Provides access to a month's worth of production history, allowing users to assess roll quality and identify defects on a digital roll map.

- Real-time notifications: Users receive timely updates on machine-related issues, including lower RPM, excessive downtime, or poor-quality rolls, enabling data-informed decisions to address these concerns promptly.