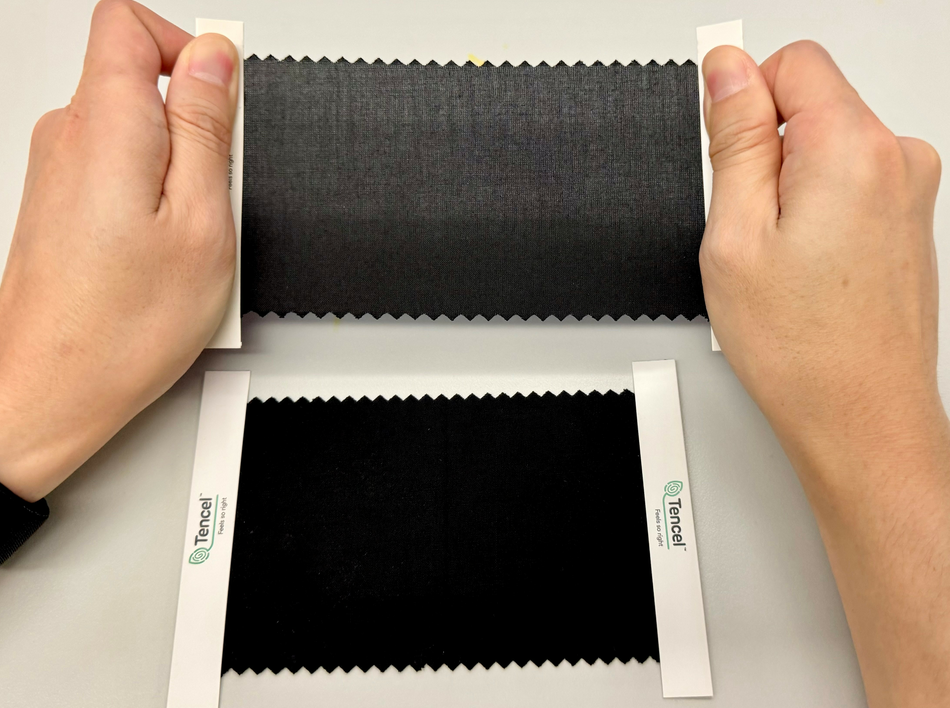

Lenzing's new processing technique for wood-based Tencel Lyocell fibres is tailored for stretch fabrics with “enhanced” recovery properties and is said to offer enhanced comfort and more design possibilities for lightweight apparel.

One of the key features of Lenzing's new technique involves the re-engineering of woven fabric composed of Tencel Lyocell fibres coupled with a fabric pre-treatment.

During the wet process these fibres experience swelling in diameter, resulting in increased yarn crimps in the width-wise direction.

This process, which is said to meet the international standard for fabric stretch and recovery properties, contributes to a fabric that stretches with enhanced recovery but also resists shrinking or wrinkling.

The fossil-free alternative claims to offer a seamless blend of comfort, flexibility, and ease of care whilst also aligning with sustainable and responsible production practices.

Additionally, Lenzing said the fibres are identifiable in end products and traceable back to their sources to ensure accountability and transparency in the supply chain.

“Our technical innovation unlocks the inherent potential of Tencel Lyocell fibres for producing stretch fabrics that move in harmony with the body,” said Rex Mok, vice president of fibre technical marketing and development at Lenzing.

He continued: "Together, we are taking a significant stride towards reduced usage of fossil-based materials within the textile value chain while ensuring comfort and material performance.”

Lenzing stated it is committed to supporting its mill partners in achieving the standard for stretch fabrics made using Tencel Lyocell fibres.

Lenzing added that it is dedicated to ensuring industry-wide adherence to quality standards and sustainable practices.