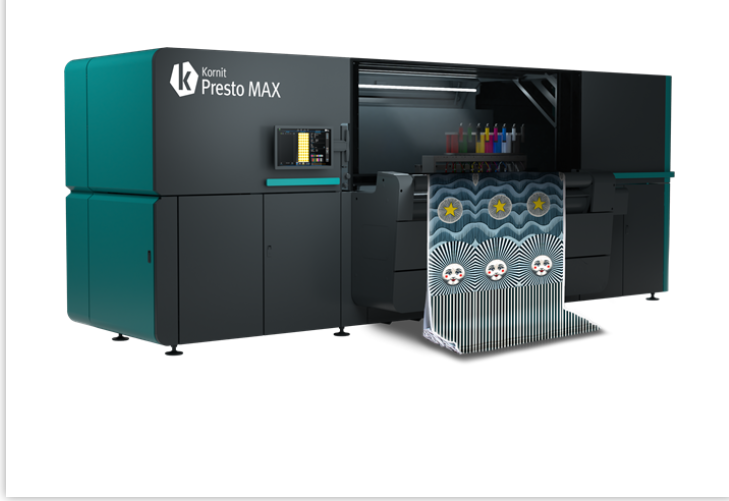

Through Kornit’s Presto Max technology, OGAT will enable brands to produce high-quality, customised garments without minimum order requirements. This on-demand approach eliminates overstock and ensures quick turnarounds from concept to finished product.

By combining Kornit Digital’s direct-to-fabric digital printing technology with an on-demand production workflow, the collaboration aims to offer fashion brands a more sustainable and efficient way to create garments.

The partnership, showcased at the Printing United Expo, seeks to address some of the long-standing challenges in fashion production, including long lead times, unsold inventory, and waste.

Paolo Roatta, CEO of Pixartprinting commented: “We are creating a brand that is truly one-of-a-kind, combining world-class digital pigment printing with the most comprehensive production and logistics workflow to produce finished garments in days with no minimum orders. Supported by a commitment to sustainability, we’re not only advancing the industry but setting new standards for how fashion is produced.”

The Presto MAX system offers enhanced printing capabilities, allowing designers to create vibrant, detailed prints using Kornit’s NeoPigment Vivido ink. The technology also reduces ink usage while maintaining quality, offering a more sustainable production process.

With the ability to customise garments down to a single unit, fashion brands can respond quickly to market trends, ensuring popular items remain available without overproduction.

Ronen Samuel, CEO of Kornit Digital, highlighted the potential of this collaboration and said: “This collaboration with OGAT and Pixartprinting is a perfect example of what single-step on-demand production can do.”

The collaboration has already been implemented through OGAT’s recent partnership with HIGH Everyday Couture, showcasing unique, custom-printed sweatshirts.