Purified shared the inception of its Hevea shoe was a four-year journey aimed at creating a "zero-plastic" shoe which is composed of Natural Fiber Welding (NFW)'s plastic-free Mirum and Pliant biomaterials.

These two materials are said to be proven to provide "micronutrients that enable future plant growth" when buried towards the end of life.

Purified explained that Hevea represents the brand's next step to counter the landfill crisis perpetuated by the modern shoe industry and replacing fossil-derived materials with biobased alternatives.

NFW's Mirum has been described as the world's "first" plastic-free, high-performance alternative to leather. Where most 'vegan' leathers are plastic and harmful to the environment, Mirum is made from plants, minerals and NFW’s patented biocurative.

The Hevea shoe's sole is made from Pliant, also described as the world's "first" naturally cured rubber outsole derived from the Hevea tree.

Purified highlighted that both biomaterials, natural and non-fossil-fuel-derived, are hand-sewn together in Portugal with cotton threads, culminating in a naturally circular shoe that can be "safely returned to the earth" with Purified's takeback scheme and NFW's EndWell programme.

Alan Lugo, NFW director of product strategy, believes NFW and Purified are changing the paradigm of footwear design.

Lugo said: "From the very beginning we have shared a desire to create a shoe that starts and ends sustainably and safely. I've been in the footwear industry in various roles for over 15 years now, and to see a team apply the same degree of scrutiny and care to sustainability as to product development is inspiring."

Purified founder and designer, Will Verona, remarked: "When I discovered NFW at the start of Purified’s journey, I knew designing a stylish, comfortable and bioneutral shoe would finally be possible. Together we are proving the industry no longer has to rely on plastics and toxic materials to create footwear. Instead, we can look to the combination of nature and technology to inspire a return to earth and transform the lifecycle of footwear."

Stephen Taylor, PhD, product circularity engineer at NFW added that crafting a sneaker using exclusively biobased materials — and testing its safe decomposition at end-of-life — is the radical approach to circularity that we need.

The Hevea shoe debuted at London Craft Week in May during a panel 'Anatomy of a Plastic-Free Sneaker.

This announcement comes shortly after Purified launched Abaca, which it said was a "breakthrough zero plastic" shoe crafted with next-generation biomaterials.

Does adoption of biomaterials indicate industry-consciousness towards circularity?

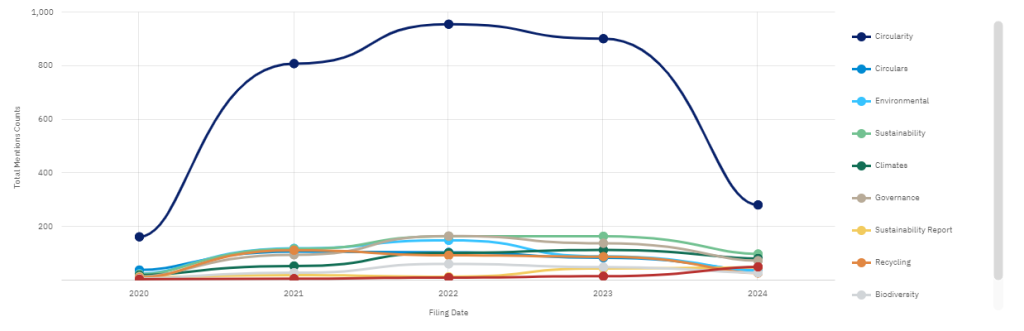

According to GlobalData's company filings data, the keyword 'circularity' peaked in 2022 with 956 mentions. Despite the decline in usage for circularity, the keyword continues to be a prominent force.

Other keywords that followed were sustainability and climate, with 99 and 82 mentions respectively in 2024 until now.

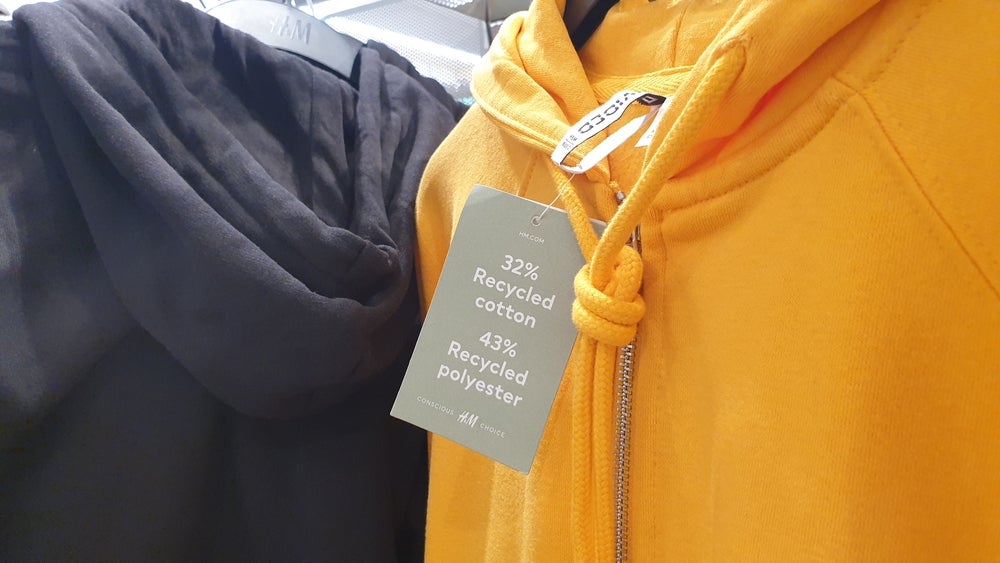

Biomaterials more specifically seem to be gaining traction in the apparel industry, especially footwear, where companies are focusing on circularity. The fashion sector has seen a rise in mentions of circularity as a predominant theme, indicating a growing focus on sustainability and circular practices.

Several companies in the industry are actively working on developing and using sustainable materials. For example, UK shoe manufacturer Vivobarefoot has introduced a scan-to-print circular barefoot footwear called Vivobiome, which uses 3D printing technology and aims to reduce waste significantly.

In another collaborative effort, Vivobarefoot collaborated with textile-to-textile recycling company Circ to develop circular solutions and design footwear uppers that can be chemically recycled and reused in the production of new footwear without the need for virgin materials.

Additionally, US sustainable footwear and apparel retailer Allbirds open-sourced the production methodology for its M0.0NSHOT net zero carbon shoe.