3DBT hopes its lab-grown leather will help the luxury end of the fashion industry to meet the ever-increasing demand for "environmentally and animal-conscious alternative leather products."

The sustainable leather alternative is produced as a 'tissue-engineered skin' grown solely from cells with tanning expertise provided by the University of Northampton.

3DBT explained its tissue-engineered skin uses only immortalised cells - isolated and collected from an adult female horse following a strict and painless bioethics process – to produce a skin/hide structure in a lab over six weeks without the use of any additional supporting materials such as plastics or cellulose in the final skin product.

The process makes use of 3DBT's patented serum-free and animal-free cell culture media supplement, City-mixTM, which accelerates tissue production whilst reducing the cost of the production process.

3DBT emphasised its lab-grown leather is, therefore, 100% animal tissue but without any animals harmed in the process as well as 'rationally designed' which facilitates novel tanning methods to help address the environmental concerns with current tanning processes.

The company suggests this process could be used for manufacturing footwear, apparel, handbags, furniture, fashion, automotive and accessories.

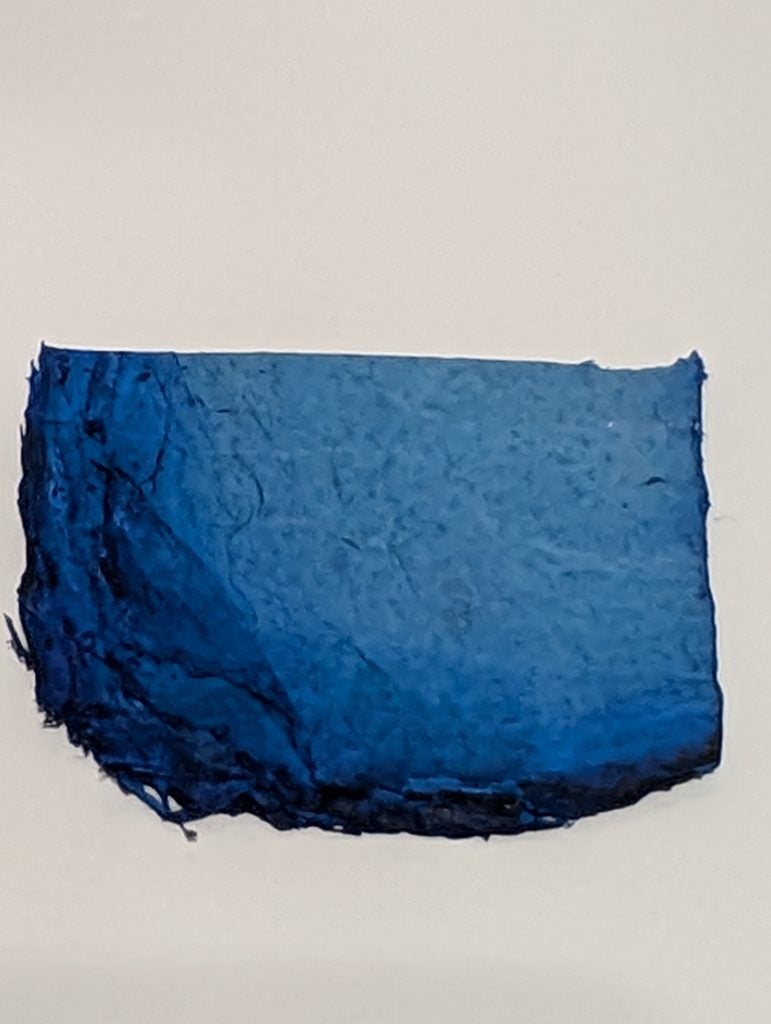

The 3DBT team unveiled the bio-engineered samples that are structurally and genetically identical to traditional leather at the Future Fashion Expo, which is taking place in London on 25 and 26 June.

The company pointed out that, unlike farm-based leather, lab-grown leather is made without harming any animals but can still be tanned using either traditional leather production processes or modern ecologically sensitive approaches, resulting in a material as diverse in colour and appearance as classic leather.

It also shared that for the consumer, lab-grown leather can also overcome many of the limitations of farm-grown leather as animal skins and hides are limited by the size, skin thickness, and life of that animal, leading to inconsistencies and imperfections in the final leather. In contrast, lab-grown leather production can be more consistent, featuring uniform composition and thickness, free of natural imperfections, and can be scaled to produce a larger material.