Sustainable fashion brand and textile innovator, Unspun, has successfully raised $14m in a Series A funding round to implement its 3D weaving technology, Vega.

The investment was led by Lowercarbon Capital, with participation from climate capital, SOSV, Signia Ventures, and MVP Ventures.

The funding will primarily support the expansion of Unspun’s Vega 3D weaving manufacturing operations, following the successful securing of multi-million-dollar contracts with partner organisations.

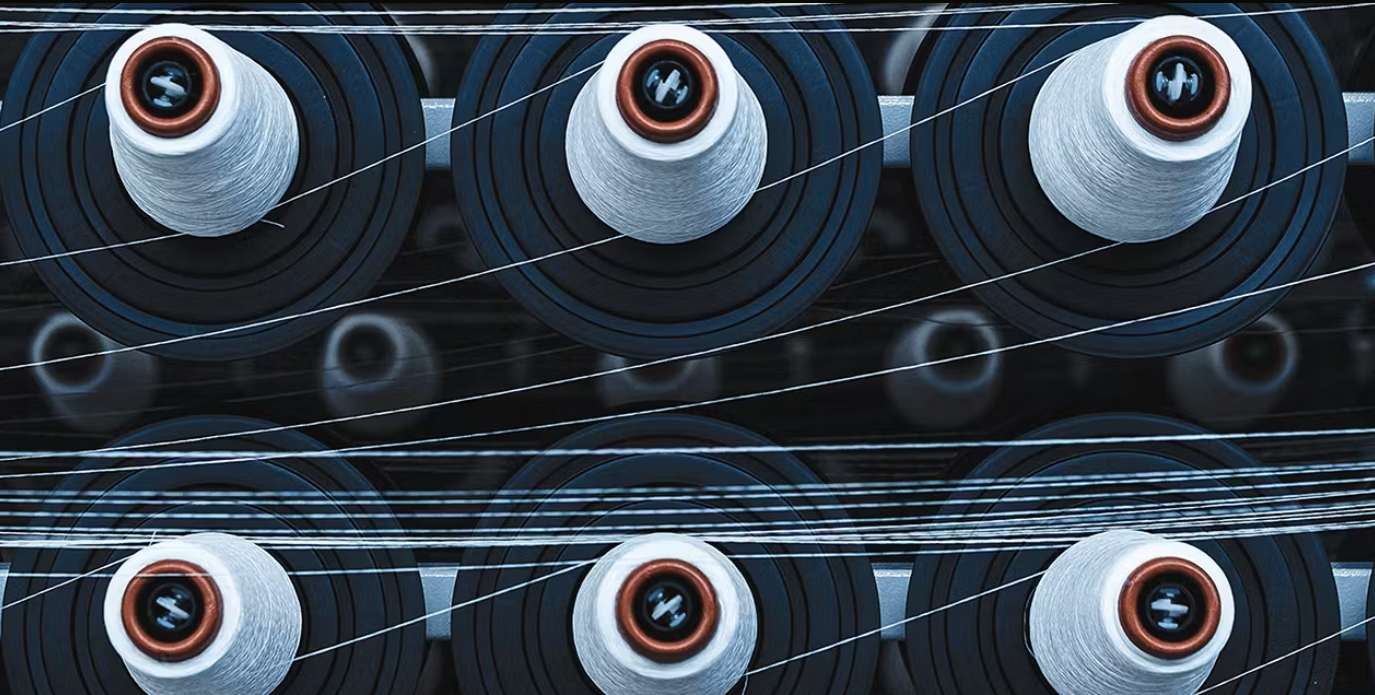

According to Unspun global waste is projected to increase by 70% by 2050 and its Vega 3D weaving machines address the urgent need for sustainable production methods. Powered by the company’s proprietary robotic technology, these machines can weave a pair of pants in under 10 minutes directly from yarns, drastically reducing the time required for finishing steps.

By leveraging Vega, brands can achieve on-demand, zero-inventory production, resulting in reduced transport costs, emissions, and a leaner supply chain. This transformative approach enables products to be manufactured just in time or on demand, minimising waste and providing brands with greater control over their inventory.

Shuo Yang, Partner at Lowercarbon, lauded Unspun’s ability to reduce emissions across the fashion industry while maintaining quality, speed, and scalability. Yang expressed confidence in Unspun’s competitive edge, stating, “Unspun is going to win because it’s going to be the most competitive way to make clothes, period.”

The unspun team has been rigorously testing and refining the Vega weaving process, with plans to introduce consumer products and additional partnerships later this year.

To showcase the efficiency and effectiveness of onshore production, Unspun will establish its first micro-factory in Oakland, California. Equipped with multiple Vega 3D weaving machines, the micro-factory will demonstrate the power of localised and automated production.

By operating in micro-factories utilising Vega, traditional manufacturing processes that contribute to high order quantities, long lead times, excessive transport emissions, and surplus inventory waste are eliminated. Adopting smaller batch production enables brands to respond swiftly to market demands or even produce items on demand, eliminating the need for inventory altogether.

Walden Lam, the co-founder of Unspun, emphasised the company’s dedication to climate action, stating: “This is the first major investment made by Lowercarbon in the fashion space, underscoring our potential to create sea-change across an entire industry. We are excited to partner with the most ambitious apparel brands and designers to solve the existential crisis facing the industry, and Vega is an important step on this journey.”

The technology holds circular applications, as Unspun is actively developing products and manufacturing techniques that facilitate the unravelling of garments back into yarns, which can then be rewoven into new products. This circular approach aligns with the company’s commitment to reducing waste and promoting a sustainable fashion ecosystem.

Notable previous investors, including Josh Buckley, Lachy Groom, 50Y, the Mills Fabrica, Novetex, and Straubel Foundation, along with several climate-tech angel investors, also took part in this funding milestone.