The Lycra Company’s new EcoMade offering is a bicomponent fibre engineered to “optimise the performance and comfort of knits”.

Lycra FiT400 fibre is composed of 60% recycled PET and 14.4% bio-derived resources and has Global Recycled Standard (GRS) certification.

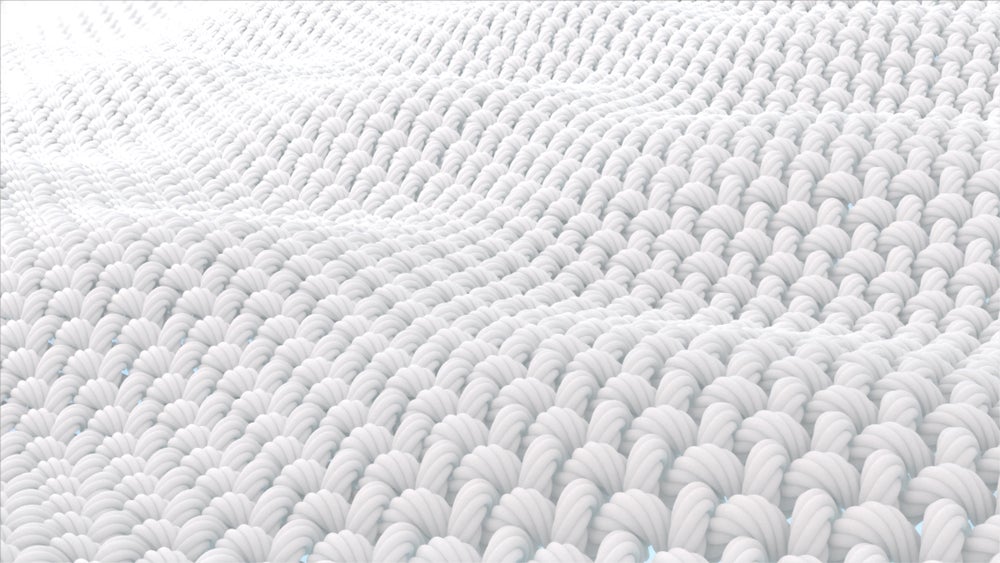

The fibre is made with two polyester polymers, creating a helical crimp that claims to provide permanent stretch and recovery properties as well as breathability, cooling comfort and chlorine resistance.

The fiber also boasts a durable soft hand-feel, low shrinkage and high fabric uniformity.

The Lycra Company claims that controlled tests have shown the technical feasibility of recycling the fibre back into new polyester fibres under specific conditions.

Steve Stewart, chief brand and innovation officer at The Lycra Company, said: “We developed Lycra FiT400 fibre to deliver in-demand performance benefits and an enhanced soft hand to the knit fabric category.

“This innovation also meets customer and consumer expectations for more sustainable solutions since it is made with recycled and bio-derived materials.”

The promotion of Lycra FiT400 fibre is said part of Lycra’s “It’s Time for Better” campaign, aiming to impact the activewear, athleisure and swimwear categories with improved functionality and reduced environmental impact.

Fabrics and garments made using Lycra FiT400 fibre may qualify for Lycra’s Xtra Life or Coolmax EcoMade brand hangtags, subject to specific brand quality standards.