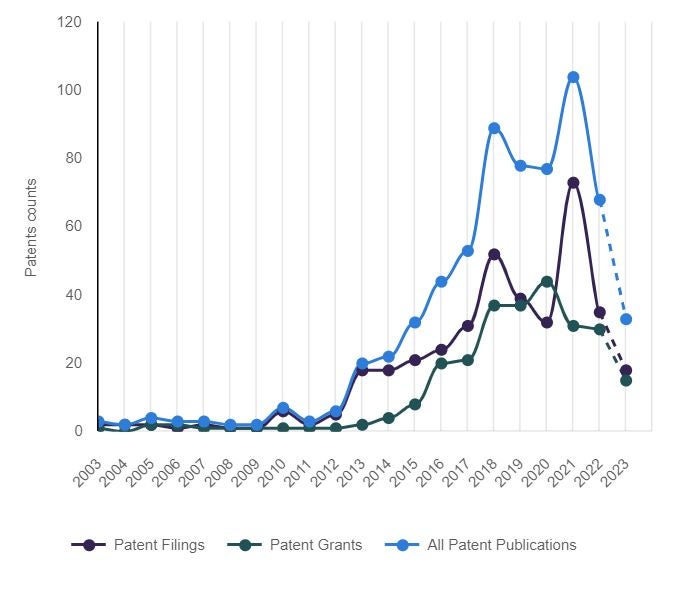

Data revealed by Globaldata suggests robotics patent publications in the apparel sector over the last 20 years peaked in 2021 at 104 before falling to 67 last year. Patent filings stood at 73 in 2021 before falling to 34 last year.

So far for 2023, robotics patent publications are at 33 while patent filings are at 18.

Robotics patent activity in apparel sector over last 20 years

Source: GlobalData

The data suggests sportswear firms are the most active when it comes to robotics patents. In the last 20 years, US sportswear brand Nike had 360 patent publications. Japanese sportswear brand Asics followed with 13 and German sportswear brand Adidas with seven.

Nike is arguably one of the most innovative players in the apparel space and it was the only apparel company in the patent assignee top 10 list for Q2 2023.

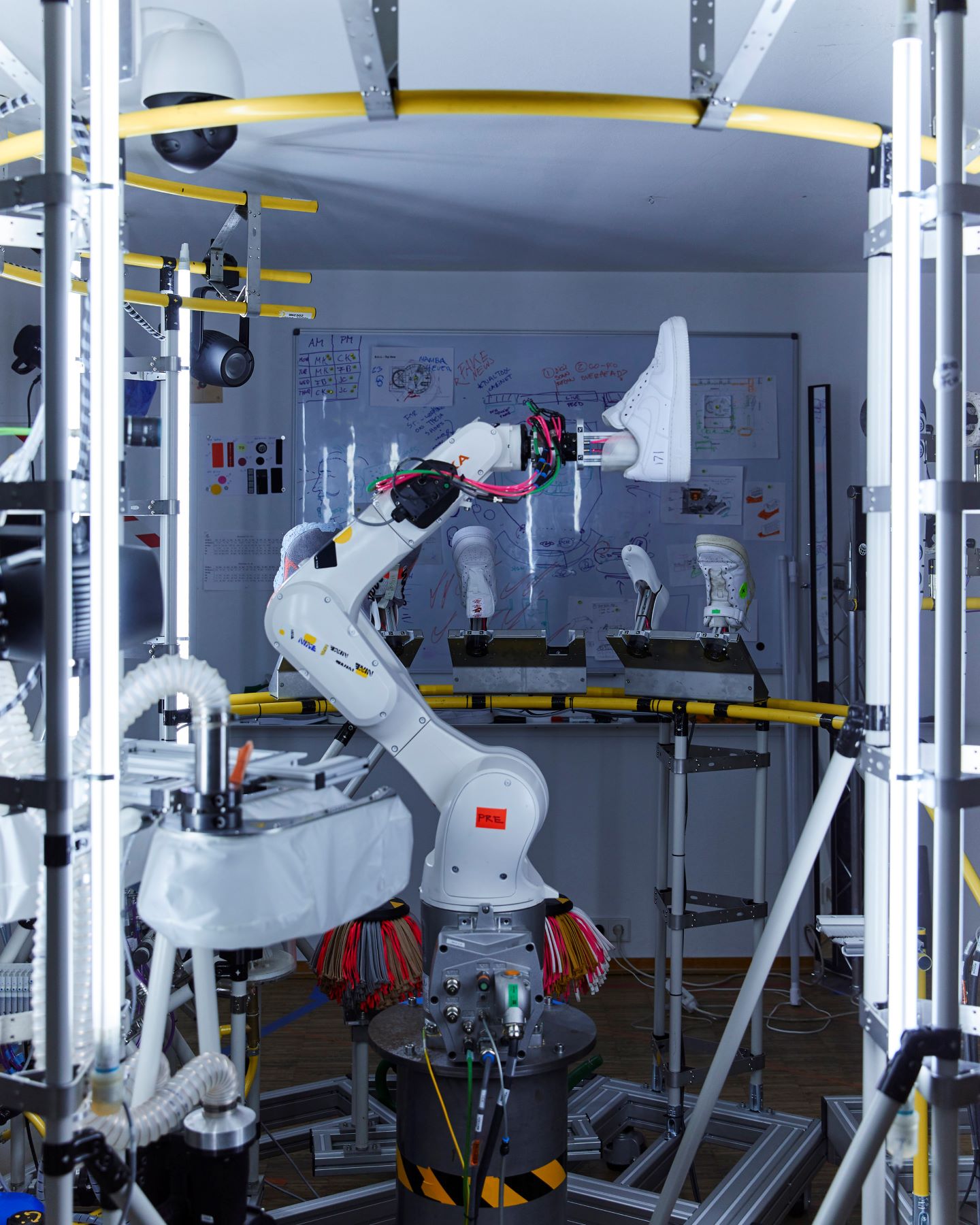

When it comes to how Nike is incorporating robotics into its operations, we can consider its robot-powered system for footwear, the Bot Initiated Longevity Lab (BILL), which it designed to extend the life of its sneakers as part of its Move to Zero initiative. Nike explained that using robotics as part of recycling technology to give products a second life reduces its environmental impact on the planet.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataMeanwhile, Asics introduced an automated shoe production system using industrial robots for lifestyle shoes at Sanin Asics Industry Corporation (SAI), Asics’ only shoe production base in Japan.

The new system partially automates the process of bonding together the upper and sole of the shoe. A robotic system pre-treats the adhesive surface with plasma, and then applies adhesive to bond the upper and sole together. The system was conceptualised and designed by the Asics Institute of Sport Science (ISS) using data gathered through decades of footwear research and development. The system’s robotic components were made by YASKAWA Electric Corporation, one of the world’s leading industrial robotics companies. With the recent introduction of the automated production process at SAI, per-worker output can be increased by roughly 40%.

Adidas, back in 2020, developed STRUNG, an industry-first textile and creation process that allows it to input athlete data into the precision placement of each thread in any direction it chooses.

“We can build and test different structures in the software before sending our chosen design to the STRUNG robot, which places each thread into a single composite with specific performance zones and properties. The result is a lightweight upper that’s precisely fitted for support, flex and breathability – all within one piece of material,” the German sportswear giant said.

Our signals coverage is powered by GlobalData’s Thematic Engine, which tags millions of data items across six alternative datasets — patents, jobs, deals, company filings, social media mentions and news — to themes, sectors and companies. These signals enhance our predictive capabilities, helping us to identify the most disruptive threats across each of the sectors we cover and the companies best placed to succeed.