Myant Inc, which is pioneering the application of technology and soft electronics into textiles, has committed $100m to an advanced manufacturing supercluster in Toronto as it prepares to launch its own brand of patented ‘Made in Canada’ smart clothing.

The facility is part of a $950m national supercluster programme from the Government of Canada’s Innovation and Skills Plan that brings together over 100 academic institutions, not-for-profit organisations, healthcare groups and manufacturers.

“We believe that The Supercluster Initiative will address significant gaps in the existing advanced manufacturing ecosystem on which we depend,” says Tony Chahine, CEO and Founder of Myant.

“If it’s done right, it will generate tangible results and funding for people who want to create and innovate, right here in Canada. I believe that in order to allow for true innovation, one needs to be able to actually ‘make’ the invention. The quick turnaround from prototyping to full scale production is the missing link to advanced manufacturing.”

Also based in Toronto, Myant employs over 80 engineers, data scientists, software developers, fashion designers and “user experience experts” who are building a computing platform that ambiently interfaces with humans through textiles.

The company develops smart-textiles for sectors including automotives, aerospace, energy, health/wellness and defence by seamlessly embedding sensors and actuators into everyday textiles allowing for 24/7 connectivity.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

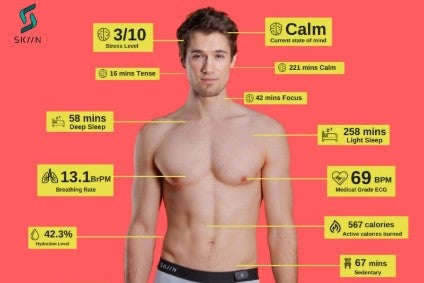

By GlobalDataIt is also in the process of expanding its facilities and adding new equipment and staff as it begins manufacturing its own in-house brand, SKIIN (the “ii” denotes “intelligent interface”), a line of smart textile and apparel such as underwear, bras, base layers, socks, mattress covers and seat covers that provide a direct conduit to the human body.

SKIIN’s smart clothing and textiles, combined with an app and cloud infrastructure, will create access to the ‘Internet of Things’ and enable a person to continuously monitor the body’s vital signs, measure activity, understand mood, control the connected environment, heat up when cold, anticipate illness, and deliver therapy, “with more advanced functionality than the world has ever seen in textiles,” the company claims.

Unlike current wearable technologies on the market, which are primarily plastic single purpose gadgets and devices, SKIIN is described as comfortable, washable, seamless clothing that collects multiple data points from a single garment.

The underwear prototype is currently being beta tested and will go to market next year.

Myant operates out of an 80,000 sq ft facility that includes an end-to-end textile supply chain with a state-of-the-art robotic knitting division, a printed electronic lab, and a traditional cut and sew operation.