Puma worked with US upcycler Andrew Burgess and his brand Vivid Visions to create five designs made entirely from Puma’s recycled polyester RE:FIBRE fabric.

Puma has also revealed it is scaling up its textile recycling innovation which started with the RE:FIBRE fabric being launched as a pilot in 2022.

From 2024 official Puma football replica jersey,s including those for the Euro and Copa América tournaments, will be manufactured using RE:FIBRE recycled materials, made from old garments and factory waste rather than only recycled plastic bottles.

PUMA CSO Anne-Laure Descours explained: “Rethinking how we produce garments and experimenting with ways that we can move towards a more circular business model is one of the main priorities of our sustainability strategy.”

Puma’s RE:FIBRE fabric is created using a four-step process. It starts with collecting and sorting textile waste, and other previously waste materials. It moves onto being shredded and mixed down to the minimum.

The next stage is to melt down the shredded polyester and remove previous dyes through a chemical recycling process.

Finally, the melting allows newly produced polymers to become ready to be spun and sewn into shape to create the new RE:FIBRE fabric, which can be recycled again and again.

Burgess was inspired by the progress Puma had made in scaling up its circular textile technology to produce his own bespoke RE:FIBRE fabric from recycled polyester garments.

He said: “Seeing the innovation, research, machinery, sustainable practices and production that goes into crafting RE:FIBRE fabric was eye-opening. When I think of garment production, I think of the final sewing stage where the fabric comes together to make the finished product as that’s typically my upcycling process. But learning exactly what goes into breaking down old textiles – that would potentially have otherwise gone to landfill – before they become something new was super interesting.”

Nike, Adidas lead the way on recycled fibre patents

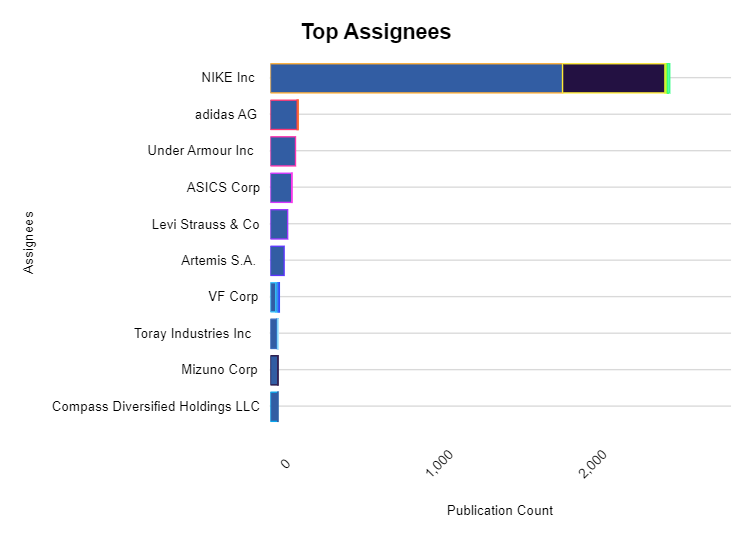

As Puma moves forward with its recycled fibre sustainability strategy, GlobalData’s patent data suggests its main competitors US sports brand Nike and German sports brand Adidas are still ahead in terms of recycled fibre patents.

Source: GlobalData

The data shows that between November 2020 and November 2023 Nike Inc had 2,528 recycled fibre publications in total with 1,262 applications and 1,256 grants.

Meanwhile, Adidas had 175 publications in total with 99 applications and 73 grants.

Other fashion brands submitting recycled fibre patents included US sports brands Under Armour and Asics Corp as well as US fashion companies Levi Strauss & Co and VF Corp.

Our signals coverage is powered by GlobalData’s Thematic Engine, which tags millions of data items across six alternative datasets — patents, jobs, deals, company filings, social media mentions and news — to themes, sectors and companies. These signals enhance our predictive capabilities, helping us to identify the most disruptive threats across each of the sectors we cover and the companies best placed to succeed.