Shein produced roughly 380,000 denim items using the Cool Transfer Denim Printing technology, which was a significant increase from the 200,000 items it produced in 2023. It has also resulted in water savings of over 10,000 metric tonnes (mt) relative to traditional methods.

Developed by global textile innovation and solutions company Next Technologies & Xvantages (NTX), the waterless colouration technology Cooltrans, which Shein calls Cool Transfer Denim Printing, was adapted for the denim industry. German sports brand Adidas was the first major customer for the technology.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

According to NTX, the technology reduces use of water and energy compared to traditional denim manufacturing processes and streamlines production.

Conventional denim production is typically resource-heavy, consuming large quantities of water and energy during dyeing, bleaching, and washing stages. To address these issues, Shein initiated a collaboration with Shanghai and Singapore-based NTX in 2021 to implement Cool Transfer Denim Printing.

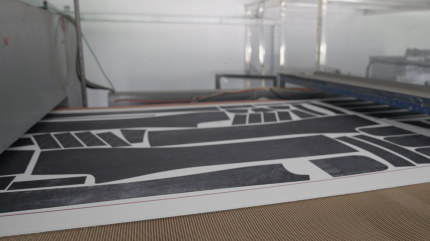

The printing method uses a digital printer that applies reactive ink onto a transfer film to create denim textures and patterns. These designs are then cold-transferred onto white denim fabric, achieving effects similar to those of washed denim such as fading and retro-worn looks.

An assessment by Bureau Veritas in October 2023 confirmed that this method cuts down water use by 70.5% when compared with standard denim washing techniques.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataSince the adoption of waterless dyeing solution in 2022, Shein has conserved close to 19,500mt of water.

Moreover, the Cool Transfer Denim Printing process is said to minimise worker exposure to hazardous chemicals commonly used in traditional denim manufacturing. By doing so, Shein aims to improve workplace safety for employees involved in denim production.

According to Shein, its on-demand business model is complemented by the integration of Cool Transfer Denim Printing. The company employs a digitalised supply chain to align product offerings with consumer demand closely.

Initial small batches of new products are released, customer feedback is monitored in real-time, and restocking occurs based on actual demand. This strategy helps prevent overproduction and surplus inventory.

The company said the technology supports small batches by “simplifying denim manufacturing and enabling precise replication of intricate designs and effects”. This also allows it “to produce denim pieces to meet demand, while at the same time working towards reducing any additional waste”.

Cool Transfer Denim Printing is fuelling creativity at Shein by offering designers unmatched flexibility to create intricate, vibrant prints that traditional methods couldn’t achieve. The technology also allows for precise replication of denim textures, enabling unique designs that cater to diverse customer tastes and push fashion boundaries.

This initiative is central to Shein’s strategy to revolutionise manufacturing, improve resource efficiency, and drive innovation in the fashion industry.

Recently, experts suggested that Shein’s lack of transparency on whether Xinjiang cotton is used within its supply chain at a UK hearing “could hold its IPO ambitions back”.

During a British parliamentary hearing last week, Yinan Zhu, Shein’s chief legal officer for the Europe, Middle East, and Africa region, was unable to reassure British lawmakers that the company’s products are free from cotton sourced from China’s Xinjiang region, an area accused of using forced labour involving the Uyghur population.