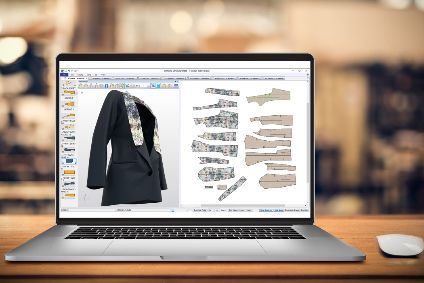

The latest release of Gerber Technology’s AccuMark 3D pattern design platform leverages simulation technology to ensure the 3D model seen on screen is production ready – helping to speed the flow of data from design to manufacturing.

The new AccuMark 3D version 12.1 lets users virtually visualise a design concept on a 3D model, enabling them to make real-time design iterations, helping to reduce sampling time and integrating the flow of data from design to manufacturing to get new styles to market faster.

As such it is also a fit tool as simulations expose pattern and fit errors, the company explains.

“Our customers are embracing a new pace in the way they design, develop and produce fashion,” says Mary McFadden, vice president of CAD Product Management at Gerber Technology.

The newest AccuMark 3D, she adds, “leverages our best in class Avametric simulation technology. With these innovations, our customers are finding AccuMark 3D can be trusted as a reliable fit tool as simulations expose pattern and fit errors that need to be fixed.”

By ensuring the 3D model on screen is actually production ready, the new release is a significant step forward in the AccuMark 3D platform, Gerber says, making pattern validation easier and faster by adding 3D simulations within Gerber’s core AccuMark 2D pattern design software (PDS).

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataIn version 12.1, updates made in 2D can also be quickly visualised and tested with tension mapping in 3D to ensure the perfect fit and improve speed in the design process. And pattern makers can see production patterns in the same window as the 3D simulation, which contributes to accuracy of the final product and increases efficiency in the overall product design and development workflow.

Coupling 3D visualisation with 2D patterns ensures the garment can be produced technically correct without additional operations, helping to save brands time and allowing them to deliver high-quality garments in a more sustainable way.

The 3D simulations can also be exported as a shareable file that allows team members without AccuMark to view it in 3D. The file can be viewed within applications like Gerber’s YuniquePLM, where product teams can add comments and annotations. Recent updates also enable AccuMark to be launched from within YuniquePLM, the company says, improving collaboration and enabling quicker iterations on styles.

Marta Bosch, chief operation officer at Spanish womenswear manufacturer Happypunt, says the pace of Gerber’s updates and new features is helping “us realise greater overall efficiency in our product development process.”