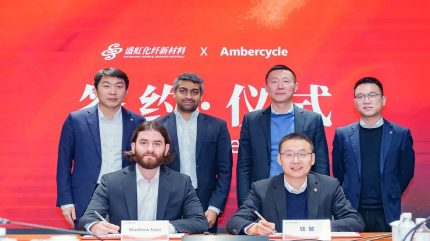

The collaboration with Shenghong aims to upscale the production of regenerated filament yarns using cycora, a material developed by AmberCycle.

Ambercycle and Shenghong have been collaborating since 2024 to produce high-quality regenerated filament yarns using cycora material.

Presently, a minimal fraction of textiles at the end of their lifecycle undergo recycling within closed-loop processes. Cycora replaces conventional virgin inputs with textile-to-textile regenerated materials, enabling brands to incorporate sustainability into their supply chains effortlessly.

This partnership places cycora within the Chinese value chain and hopes to help meet the global demand for sustainability in the fashion industry. It is said to represent a significant step towards a circular economy where waste is transformed into a valuable resource.

Shenghong Chemical Fiber New Material general manager Jason Tang said: “As the industry adopts textile-to-textile solutions, cycora is leading the way in delivering materials that meet the demands of global brands. This partnership is pivotal in driving scalable, impactful change across the apparel sector.”

The combination of Shenghong’s expertise in yarn manufacturing and AmberCycle’s approach to circular materials is expected to significantly scale up the production of textile-to-textile filament yarns for widespread use.

Shenghong is a large producer of recycled polyester from bottles and hopes to propel circularity forward by adopting textile-to-textile solutions through the cycora material.

AmberCycle co-founder and CEO Shay Sethi said: “Our partnership with Shenghong underscores our shared vision for a circular future. By leveraging Shenghong’s advanced manufacturing capabilities, we can ensure cycora is seamlessly integrated into the supply chains of leading global brands. Together, we’re not just scaling production; we’re driving the adoption of circular materials across the apparel industry at the pace necessary to meet the growing demand.”

Furthermore, AmberCycle sees its new partnership with Benma Group as enhancing circularity in textiles through the production of cycora fibres. This collaboration is said to broaden the cycora product range that is available to global brands by introducing premium quality staple fibre.

The synergy between AmberCycle’s technology and Benma’s manufacturing infrastructure offers a robust foundation for innovation and growth in circular textile solutions. Benma’s direct investment in AmberCycle’s expansion efforts signifies their mutual dedication to accelerating this transition.

With an anticipated annual demand for decarbonised polyester reaching 7m metric tonnes (mt) by 2026, the urgency for scalable and innovative solutions is palpable.

Sethi added: “Partnering with Benma allows us to expand cycora’s potential by diversifying its applications into staple fibres. Their investment in our scale-up efforts underscores a shared commitment to innovation and sustainability. This collaboration not only supports our ability to scale but also creates new pathways for brands to integrate circular materials into their supply chains and products.”

In June last year, Hyosung TNC, a provider of sustainable textile solutions, teamed up with Ambercycle to become the first manufacturer in South Korea to incorporate textile-to-textile circular polyester into brand supply chains.