Just-in-time (JIT) production methods have already slashed the lead times for sewing, while modern logistics mean goods can be delivered quickly, however creating the initial design and providing colour options and size grading for samples can take days to develop.

What if the apparel industry could reduce the number of rounds needed down to one, and go straight into production? Here, Just Style explores the latest 3D rendering tools and communication platforms that are speeding up apparel lead times significantly.

3D rendering software has transformed how the global apparel industry communicates, designs, creates prototypes and ultimately makes garments. By adopting digital-only creation, the industry has adapted to the ‘new normal’ with end-to-end digitalised product development, communication and management. For those working in the sector, the use of 3D rendering has revolutionised the way garments are designed. And the technology arrived when it was needed most — during the pandemic.

“The accelerated progress we have made as an industry would have been unimaginable pre-pandemic. We have learned a lot in a very short space of time,” explains Janice Wang, CEO of apparel technology company Alvanon Inc.

She adds: “Digital fashion is currently a US$40bn market and growing. As the wearer base and enabling technology expands, it’s very important for future designers to know about the skillset they need to develop.”

Replace physical prototyping with 3D rendering

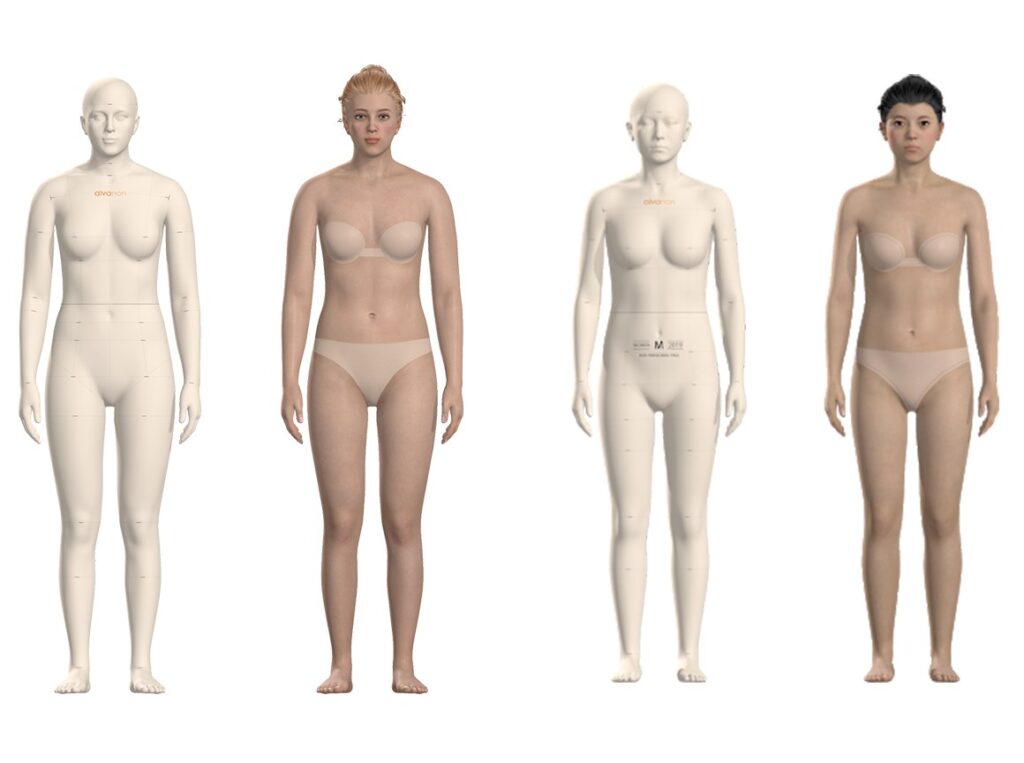

Alvanon aims to help apparel brands and retailers with their fit and sizing strategies. It also offers solutions that include data gathering and analytics, dress forms, product development and supply chain optimisation. Once created, apparel prototyping can be drastically reduced using 3D avatar fit models.

“Alvanon was founded in 2001 by my father, Dr Kenneth Wang,” Alvanon’s chief operating officer Jason Wang told Just Style. “He was a visionary, always looking for better ways of doing things. In the 1990s, he built the world’s first body scanner, using cameras that went around the body on a track. When the internet appeared, he instantly recognised its potential for selling clothes and transforming the fashion industry.”

Wang explains the company was founded with a vision that the apparel industry would be developing, marketing and selling garments digitally at some point. He says: “It’s taken much longer than we anticipated for the industry to digitise. Around four years ago we saw 3D software was being adopted by our clients and we launched the Alvanon Body Platform in January 2019.”

The industry had already started its journey towards digitalisation, however Wang points out it was the pandemic that was the catalyst for change. Recent advances in software design and 3D rendering – powered by technology developed for the gaming industry – have progressed 3D garment design to new levels of sophistication and realism. With travel curtailed, close working banned and logistics badly affected, the fashion industry had to accelerate its journey into the virtual realm.

“Pre-pandemic we had been working with several forward-thinking companies,” Wang explains. He adds: ”Now we are helping nearly all of the companies stuck in the old physical world of producing clothes to transform themselves to digital ways of working — allowing us to move toward [and] realise our mission of providing our retail and brand clients with the ability to make clothes that fit any (size) body.

Wang also highlights that digitisation provides the opportunity for automation or partial automation for the majority of tasks within the product development cycle. He says: “This, in turn, allows companies to become far more efficient and effective so they cannot only cut their lead times down to weeks from months, but also have a much more sustainable development process.”

Alvanon’s approach aims to support creativity but also deliver end products in a digital and sustainable way. The Alvanon Body Platform for example, is designed to provide virtual bodies (AlvaForms) that are compatible with the 3D systems its clients are using. As a result, the company’s clients can develop authentic digital garments, where they are fitted to the exact same body, digitally and physically.

Wang explains: “Through this process, authentic digital garments are created. A library of these assets becomes one of the key foundation pieces for the digital journey, allowing companies to realise their true potential in terms of digitisation.”

3D rendering

3D rendering software provider Clo Virtual Fashion, which uses its software to make CGI clothes in movies look more realistic, also creates 3D rendered designs for the apparel sector. In a recent webinar, an on-screen interface displayed a 3D virtual mannequin (avatar) with a 2D pattern template side by side. Within minutes the designer had a template constructed from what the company calls ‘blocks’ (basic pattern pieces) that were overlaid onto the avatar. As changes were made to the 3D template, the 2D pattern updated instantly. An automatic ‘sew’ command pulled the fabric pieces together, while drag and drop commands were used to apply different fabrics and displayed how the different options would drape.

The webinar explained that advanced silhouettes featuring different textures, mixtures on different panels and specific fabrics can also be simulated, and top stitching, button details and different colourways can be applied and uploaded. Finally, the pattern pieces can be nested ready for grading and cutting via CAD files.

Clo’s 3D rendering of the avatar is designed to be extremely realistic and it also features runway-style presentations that can be presented to the client. The software allows colour changes and slight adjustments to be made on the fly, which means sampling has gone from days to hours without a single piece of cloth being cut.

There is a strong argument for this business model being a more sustainable option for eco-conscious brands. The advanced processing power does have an environmental cost, but it removes the need to travel to a studio and reduces material wastage from making and remaking samples. And that’s the real time-saver. If a client changes their mind, or the fashion trend shifts overnight, a virtual 3D model can be re-rendered as many times as needed in a matter of minutes.

Alvanon’s Wang confirms this is how the apparel sector can save precious lead time. He says: “Any edits to the garments on the bodies automatically leads to a change in the pattern. No physical samples are created until everyone in the creative and technical team is happy with the virtual representation. This can save weeks of development and sampling time, especially when dealing with offshore vendors. In the future, when brands have their own libraries of digital authentic garments, where the patterns, fabrics, and trims have all been verified for production, this entire process can be automated, drastically shortening lead times.”

Accurate fitting and cutting

Apparel CAD software providers Lectra and Gerber, have created systems to reduce pattern checking times. The 3D patterns rendered in Lectra and Gerber’s digital CAD systems, called Modaris and Gerber AccuMark, feed directly into modern cutting systems.

Lectra’s corporate communications director, Olivia Riant explains that Lectra’s advanced version of Modaris, which is called Modaris Expert, links the pattern pieces together to reduce repetitive tasks and minimise the risk of error that can lead to inaccuracies.

She says: “Similarly, if a collection includes patterned fabrics, the software helps to not only identify the pattern matching points but also the related logic and keeps this information until the cutting stage.”

Riant also points out the software allows users to manage their grading constraints stress-free, using what she describes as “simple, effective tools”. She says: “In other words, you can do everything you were doing by hand, but it’s now simpler, more automated, and more reliable.” Another bonus, she says is the 3D solution can be fully integrated with a 2D CAD solution through a bidirectional link between the two environments.

Plus, precise costing calculations and fabric usage information after every pattern change can help speed up the production process and seamless integration between 2D, 3D and planning software, which allows for faster turnaround times.

Improve communication

The benefits of using 3D tools within the supply chain isn’t just about providing advanced 3D rendering, it’s also about the fact clients can download the data themselves which streamlines the conversation.

The Clo Virtual Fashion business model, for example, features what it calls the Clo-Set platform, which allows clients to download their virtual assets. Clo’s vice president of business development, Serena Kim explains during the webinar on the latest 3D technology in fashion design, that 3D tools help to prevent communication issues.

She says: “We believe that by using 3D, clients have a single language that makes the communication more efficient.” Kim also points out that stronger communication makes the process more efficient and speeds up the overall process because all associated parties are less likely to make mistakes.

If that wasn’t enough, Kim believes the benefits for companies wishing to try 3D tools is that less workarounds are needed, which reduces the cost and speeds up the rate at which the garment is ready to hit the market.

She explains that without a 3D tool platform such as Clo, workarounds would be needed on the proto sample, in terms of sample sizes, colour options, grading options and artwork options. However, she says Clo is trying to reduce the number of rounds into just one that goes straight into production.

Kim goes as far as to compare the garment process with and without 3D tools and the difference is huge She explains that before it’s 37 days of sample time with just 15% adoption rate, however with a 3D tool platform, such as Clo, clients could have a sample time of just 27 hours and an increased sample adoption rate of 55%.

In conclusion, it appears the latest innovations in 3D rendering and communication platforms are proving to be successful at bringing together both creatives and manufacturers to speed up apparel lead times.