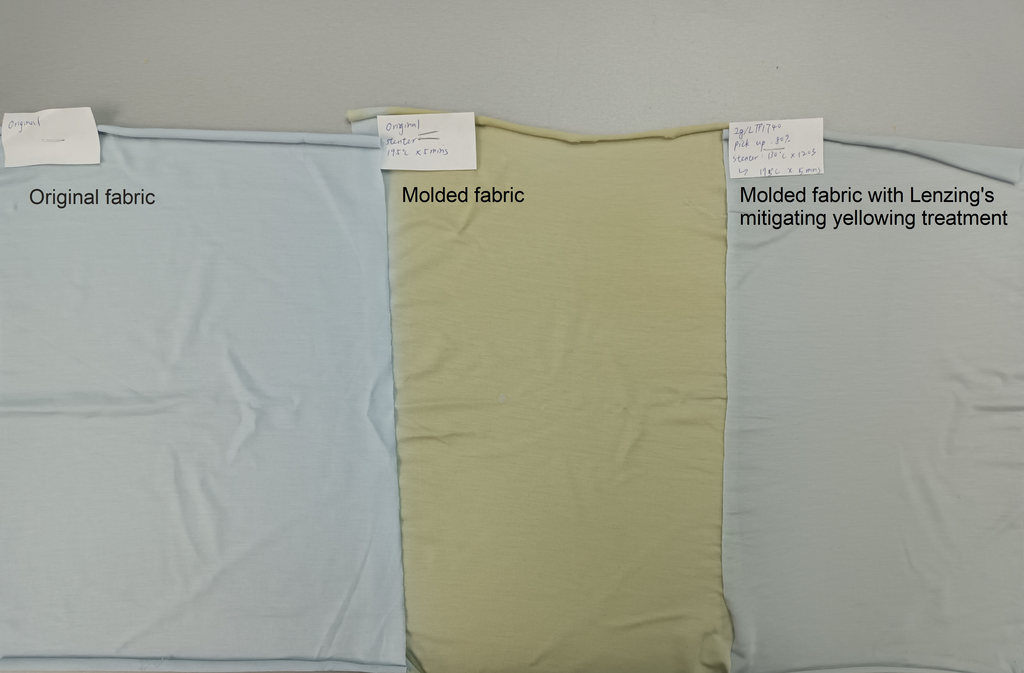

Lenzing says its proprietary innovation is the industry’s “first” solution to address the technical challenge during the garment moulding process.

The producer of speciality fibres further explained that while chemicals could be used to minimise discolouring issues in synthetic fibres, this method does not work as effectively as it does in wood-based cellulosic fibres.

However, Lenzing’s new innovation has eliminated the bottleneck fabric mills experienced during the production and dyeing of light-coloured garments made of wood-based cellulosic fibres.

This technology will initially be rolled out in the innerwear and shapewear segment. Later, it will be extended to outdoor apparel and other ready-to-wear industry segments globally.

Leveraging on this innovation, Lenzing adds that its mill partners can now benefit from the adoption of a broader spectrum of colours and shades, bringing more diversified fabric and garment offerings to consumer brands.

Moreover, Lenzing’s technical experts will work closely with fabric mills to provide a technical analysis of fibres and fabrics, recommendations, and ongoing support through to the end-garment stage.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataYelin, Lenzing’s fabric mill partner, is one of the first adopters of this technology on a commercial scale.

Rex Mok, vice president of fibre technical marketing and development at Lenzing, said: “Discoloration has long been a lingering issue for the industry. Through ongoing innovation and close collaboration with fabric mill partners, we have not only addressed a common technical challenge but also enhanced sustainability in the value chain with the potential to increase the usage of botanic fibres across innerwear and outdoor garments.

“The latest technological innovation also speaks to Lenzing’s efforts to improve and widen the application of cellulosic fibres, such as Tencel Lyocell and Modal fibres, which are derived from sustainable wood sources and produced using environmentally responsible processes. This serves as part of our wider commitment to drive the sustainable development of the textile value chain.”

In addition to this, Lenzing pointed out that it is taking the next steps to explore other potential applications, such as in heat seal processes of garments, and seamless stitching processes that involve heat seal adhesive tapes and bonding machines to replace traditional sewing.